- Phone: 306-970-1552

- connect@gentleprocessing.ca

- 18-301 South Industrial Dr. Prince Albert, SK S6V 7L7, Canada

Technical specifications

|

‘ . |

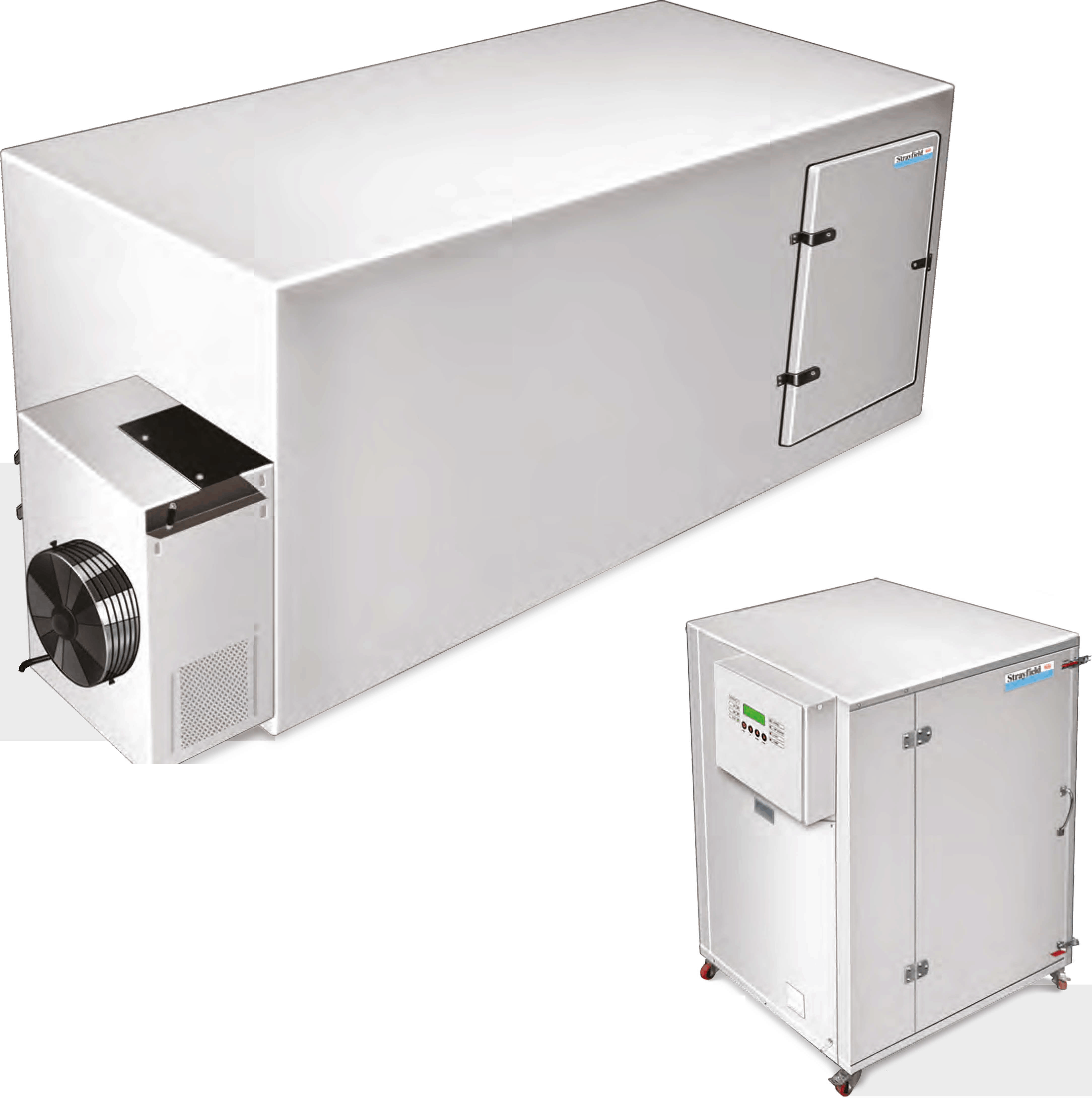

Models |

GPVC-25 |

GPVC-50 |

GPVC-100 |

GPVC-500 |

|

Batch Load Kgs*/Trays # |

25Kgs/12# |

50Kgs/24# |

100Kgs/48# |

500Kgs/240# |

|

|

Power Supply |

3 0, 410 V 50Hz |

3 0, 410V 50Hz |

3 0, 410V 50Hz |

3 0, 410V 50Hz |

|

|

Connected Load** |

1.0kW |

2.5kW |

4.0kW |

7.0kW |

|

|

Thermal Load kW |

3.5kW |

4.5kW |

6.0kW |

10kW |

|

|

Water Removal |

1.9Ltr/Hr |

3.0 Ltr/Hr |

5.0 Ltr/Hr |

15Ltr/Hr |

|

|

Dimensions (mm) |

1400x830x1370 |

1440x940x1970 |

2200x1550x2300 |

4500x2040x2200 |

|

*Specifications herein are tentative and product dependent

Nutrition retention: Traditional hot air/steam dryers operate at much higher temperatures(80 degrees Celsius +) as compared to a VC. This usually results in a breakdown of some nutrients. The VC operates between 50 to 65 degrees(Celsius).

Undamaged cell structure: Higher temperature dryers may cause spontaneous pockets of steam that damage/ rupture food cell structures. This results in a change of texture which is undesirable. Powders that have been dried/produced from a puree/slurry state in a VC can be rehydrated back into its initial state without any change in texture.

Flavor retention: for reasons mentioned in point number 1, a VC is superior as compared to a traditional dryer in flavor retention.

Energy efficiency: Traditional dryers rely on heating air which is then passed over the moist product and is eventually rejected to the atmosphere taking the heat energy and moisture with it. The VC recycles most of the heat energy(70%) it uses.

Reusable water: Following from point number 4, most of the moisture(80% approx.) in a VC is captured in liquid state to be recycled.

Color retention: Following from point number 1 ,3 and 4, higher temperature dryers not only cause a breakdown of aromatic molecules but also reject a significant quantum of these molecules to the atmosphere. The VC is a low temperature closed system that retains a significantly larger amount of flavor molecules.

No need of a furnace or boiler: Traditional boilers need a cheap source of heating. This is usually done by attaching a furnace or boiler that derive their heat from burning carbon-based fuels. There are large operating costs associated to maintaining and running furnaces and boilers( fuel costs as well as regulatory and safety costs). The VC only needs a supply of electricity. Aside, carbon-based fuels are significantly more harmful from an environmental front.